Whether developing new products or redesigning existing ones, prototyping is essential to the design process. Using prototypes to test concepts before investing in production can save time and money on the front end and reduce your risk of product failures later.

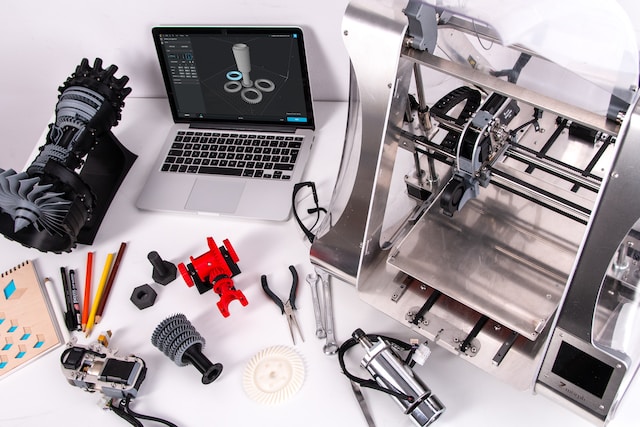

There are many ways to manufacture prototype parts, including CNC machining, polyurethane vacuum casting, and 3D printing. Each method has pros and cons, so choosing the right one for your specific project needs is essential.

Saves Time

Using prototype parts to validate your design saves time and money in the long run. You can ensure the part will function properly in production without risking significant losses, and you can iron out any issues before putting it into full-scale manufacturing.

Prototypes can be made with tools or molds or using 3D printing technologies. Molds are usually more expensive than 3D-printed prototypes, but they offer physical and dimensional accuracy advantages and processing takeaway benefits.

Prototypes can be made from a variety of plastic materials. These materials include thermoplastic, aluminum, and steel. Choosing the suitable material for your prototype can ensure your product works well in production.

Saves Money

Getting high-fidelity prototypes for testing purposes is a wise investment. They take more time to make and cost more, but they provide better data for estimating production costs.

A good prototype manufacturing firm will have a team of design engineers, tooling specialists, and quality control experts to help you turn your idea into reality. These professionals know how to work with small custom orders and can help you maintain a tight schedule while maintaining high quality and consistency.

A critical aspect of a prototype production company is that they can help you reduce the costs involved with CNC machining. A manufacturing shop can also help save you money by reducing the time it takes to set up and calibrate a machine or by using a “cellular” manufacturing approach, where all needed machines and tools are in the same area. This close physical arrangement of devices ensures that your in-progress parts are produced faster and ready to test sooner than if sent through different departments.

Saves Risk

Prototype parts are an excellent way to test your ideas before you invest in them. They can also save you money by avoiding costly mistakes or delays.

The first step in prototyping is to understand your needs. There are many types of prototypes, from simple sketches to full-blown working models.

High-fidelity prototypes are more realistic and give teams a better idea of how their product will look and perform in the real world. They can help couples determine the best features and functions to include in their development.

Low-fidelity prototypes, such as sticky notes and sketches, are ideal for brainstorming ideas with team members. They aren’t perfect representations of the final product, but they’re enough to get teams thinking about potential issues that could crop up.

Before committing to a specific prototype method, it’s essential to determine what it will cost and how long it will take to create. Then, select a supplier that can provide the right quality and turnaround time for your needs.

Saves You from Mistakes

Prototypes help you identify and fix flaws before you commit to manufacturing your product. This can save you money in the long run, ensuring your product is robust.

A prototype can show you areas that need reworking or help you decide on a new material that will work better for the design. In addition, it can be used to test how the final product will function in the real world.

A prototype can also be used to test the idea with investors or clients. It can help you see if your concept is viable and will be profitable.

When choosing a manufacturing method for your plastic and metal prototypes, you must select one that allows you to create the desired shape without compromising its strength or functionality. This means choosing a company with state-of-the-art 3D printing technology and expert technicians to make your products.